Purge™ Laminar Flow Hood / PCR Workstation

- Ultraviolet germicidal light system provides sterilization of the clean air hoods interior space

- Vertical laminar flow air provides an ideal ISO 5 (Class 100) processing environment

- Ideal for critical applications, such as DNA & RNA manipulation and amplification

- Built-in micro switch allows safe operation of the ultraviolet light source

- Integrated white polypropylene base provides a clean and chemical resistant work surface

- Fluorescent lamp provides direct lighting over the work area

- Two-piece access shield features adjustable friction hinges for safe positioning

- Offered in a variety of sizes and materials to meet application specific requirements

- Standard system voltages include 120VAC 50Hz and 240VAC 50/60Hz

- Available in a variety of sizes and materials, including static dissipative PVC for added contamination control and chemical resistance

The Purge™ Laminar Flow Hood is a complete system intended to meet the most demanding applications. An ergonomically sloped front access area affords the operator more comfort and better reach into the clean air hoods interior, while the integrated white polypropylene base provides a clean and chemical resistance work surface in which to conduct the intended procedures. The polypropylene base also increases the strength and integrity of the hoods structural body, allowing convenient portability for placement on any available table or counter top. A fluorescent lamp provides for general task lighting and an ultraviolet germicidal irradiation (UVGI) source for disinfecting micro-organisms, which when coupled with the systems HEPA filtration system, can be purged from the work environment. The stainless steel control box, which is also a code compliant electrical box, interfaces the clean air hood components into a stand-alone system with UV light system controls.

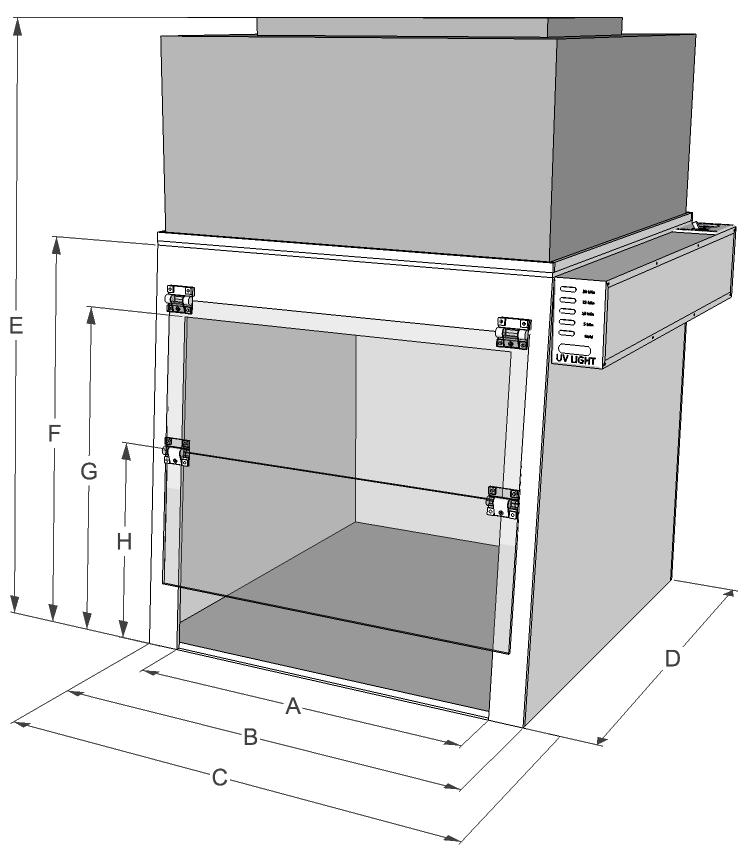

| Purge™ Laminar Flow Hood Nominal Dimensions in Inches (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Hood Size |

A | B | C | D | E | F | G | H |

| Small | 20.25″ (514) |

24.25″ (616) |

27.25″ (692) |

26.25″ (667) |

36″ (914) |

23.25″ (591) |

19.75″ (502) |

11.75″ (298) |

| Medium | 32.25″ (819) |

36.25″ (920) |

39.25″ (997) |

26.25″ (667) |

36″ (914) |

23.25″ (591) |

19.75″ (502) |

11.75″ (298) |

| Large | 44.25″ (1124) |

48.25″ (1225) |

51.25″ (1302) |

26.25″ (667) |

36″ (914) |

23.25″ (591) |

19.75″ (502) |

11.75″ (298) |

Standard Laminar Flow Clean Air Hood Material Options:

- Acrylic (cast) – Ideal for general purpose processing. Provides some chemical resistance

- Polycarbonate – High impact resistance makes this material ideal for thermal stress applications. Provides good chemical resistance

- Polypropylene – Provides the best chemical resistance

- Non-Dissipative PVC – Provides excellent chemical resistance

- Static Dissipative PVC – Provides excellent chemical resistance. Also helps to reduce contamination build-up around and within the glove box by neutralizing

static charges that attracts air borne particulate

Additional product information:

- Small and medium clean air hoods feature a solid-state speed controller and large hoods feature a three-speed switch (low-med-high)

- Access shields are made from the same material as the hood itself with exception to the polypropylene hood, which features a non-dissipative PVC access shield

(Custom sizes available upon request)

| Purge™ Laminar Flow Hood (for 120VAC, 50Hz use) | |||||

|---|---|---|---|---|---|

| Hood Size (see drawing below for hood dimensions) |

Acrylic | Polycarbonate | *Polypropylene | Static Dissipative PVC |

Non Dissipative PVC |

| Part # | Part # | Part # | Part # | Part # | |

| Small | PLF2-A1 | PLF2-C1 | PLF2-P1 | PLF2-D1 | PLF2-N1 |

| Medium | PLF3-A1 | PLF3-C1 | PLF3-P1 | PLF3-D1 | PLF3-N1 |

| Large | PLF4-A1 | PLF4-C1 | PLF4-P1 | PLF4-D1 | PLF4-N1 |

| Purge™ Laminar Flow Hood (for 240VAC, 50/60Hz use) | |||||

|---|---|---|---|---|---|

| Hood Size (see drawing below for hood dimensions) |

Acrylic | Polycarbonate | *Polypropylene | Static Dissipative PVC |

Non Dissipative PVC |

| Part # | Part # | Part # | Part # | Part # | |

| Small | PLF2-A2 | PLF2-C2 | PLF2-P2 | PLF2-D2 | PLF2-N2 |

| Medium | PLF3-A2 | PLF3-C2 | PLF3-P2 | PLF3-D2 | PLF3-N2 |

| Large | PLF4-A2 | PLF4-C2 | PLF4-P2 | PLF4-D2 | PLF4-N2 |

* Acrylic is susceptible to damage with the prolonged use of alcohol and other cleaning/disinfecting agents.

Product Options & Customization

Power Strip

- Provides an convenient electrical connection for process equipment being used within the clean processing environment

- Mounted horizontally on the inside rear wall 3” from the bottom work surface

- Includes a master on/off switch, 4-outlets and a 15-amp circuit breaker

| Power Strip |

|---|

| Part # |

| LF-PS-4 |

Spill Containment Tray

- Provides containment of liquid spills within the Purge™ Laminar Flow Hood or the Flex™ Laminar Flow Hood

- Fabricated out of ¼” (6.35 mm) white, chemical resistant polypropylene

- Removable for easy clean-up or storage when not needed

| Spill Containment Tray | ||

|---|---|---|

| Hood Size | Tray Nominal Inside Dimensions in inches (mm) |

Part # |

| Small | 17.5″W x 23.5″L x 1″D (445 x 597 x 6) |

SCT-2 |

| Medium | 29.5″W x 23.5″L x 1″D (749 x 597 x 6) |

SCT-3 |

| Large | 41.5″W x 23.5″L x 1″D (1054 x 597 x 6) |

SCT-4 |

Ion Power Bar™

- Enhances cleanliness within the hood by neutralizing static charges that attract air-borne contaminates

- Continuous generation of static neutralizing ions help to protect static sensitive materials/devices from electro-static discharge

- Ionizing bar mounts below the HEPA filter unit providing optimized distribution of both positive and negative ions

| Ion Power Bar™ | ||

|---|---|---|

| Hood Size | 120V, 50Hz | 240V, 50/60Hz |

| Part # | Part # | |

| Small | ION-2B-1 | ION-2B-2 |

| Medium | ION-3B-1 | ION-3B-2 |

| Large | ION-4B-1 | ION-4B-2 |