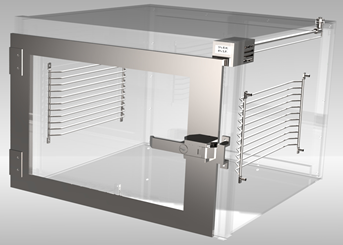

AutoDesiccator™ Cabinets / Dry Boxes

- Built-in control system automatically maintains the relative humidity to the user selected level

- Integrated LCD continually displays the relative humidity level within the desiccators storage chamber

- Stainless steel door frame that re-enforces and protects the plastic door from damage

- A re-enforced “hat” section that stiffens and eliminates door flex, ensuring a positive seal across the full length of the door

- Door design that securely holds in-place, without adhesive, a one-piece, non-outgassing , non-deforming elastomer gasket that provide optimal long-life sealing performance

- Heavy-gauge stainless steel wrap-around hinges that eliminate “hinge point compression” of the gasket material (typical of piano style hinges), increasing the life of the door seal

- Precision machined billet aluminum and chrome plated compression lift latch that opens and closes without over straining the cabinet door

- Chrome plated side racks are that accommodate optional storage shelves and trays

- Auto-Adjust™ RB Valve that maintain a safe operating pressure within the Auto™ Desiccator Cabinet and with its one-way air flow design, acts as a check valve

- Offered in several sizes and materials, including static dissipative PVC for added cleanliness and static control

System Overview

The system features a miniature controller with a built-in alpha/numeric display (LCD with LED backlighting) and packaged within a small stainless steel housing, which is placed within the storage chamber, requiring no external control devices. Once final set-up is complete and the desired humidity set-point level is selected, the controller will activate the flow of dry gas (nitrogen preferred) to reduce the humidity level down to the user selected set-point (factory set to 15% RH). Upon reaching the RH set-point, the controller will cycle off the flow of dry gas until such time as the system senses another purge of dry-gas is needed or the access door is opened. All the time, the humidity level within the storage chamber is being displayed on the LCD. In addition to displaying the chambers internal RH level, its alpha/numeric display allows for quick and easy adjustment of system perimeters, if and when needed. System audible/visual alarms indicate if the access door is left open longer then setting or if the system “purge” mode is on for too long a duration without reaching the relative humidity set-point, indicating a possible problem with the dry-gas supply. To protect the desiccator cabinet against over-pressurization, it is fitted with an Auto-Adjust™ relieve & bleed valve, which helps maintain a safe operating pressure. Power: 120/240VAC, 50/60Hz (universal with automatic power selection).

| AutoDesiccator™ Cabinets / Dry Boxes | ||||||||

|---|---|---|---|---|---|---|---|---|

| AutoDesiccator Series # |

Desiccators Nominal Overall Cabinet Dimensions in inches (mm) W x D x H |

Number of Chambers |

Chamber Access Opening (nominal) in inches (mm) W x H |

Chamber Nominal Inside Dimensions with Side Racks in inches (mm) W x D |

Shelves / Trays Nominal Inside Usable Dimensions in inches (mm) W x D |

Clear Acrylic* |

Amber Acrylic* |

Static Dissipative PVC** |

| Part # | Part # | Part # | ||||||

| AD112 | 13″ x 12.25″ x 13.5″ (330 x 305 x 343) |

1 | 10.75″ x 10.4″ (273 x 264) |

9.7″ x 11.5″ (246 x 292) |

9.5″ x 10.75″ (241 x 273) |

AD112-1C | AD112-1A | AD112-1D |

| AD116 | 17” x 16″ x 9.5″ (406 x 406 x 203) |

1 | 14.75″ x 6.4″ (375 x 163) |

13.7″ x 15.5″ (347 x 394) |

13.5″ x 13″ (343 x 330) |

AD116-1C | AD116-1A | AD116-1D |

| AD118 | 18.5″ x 18″ x 13.5″ (470 x 457 x 343) |

1 | 16.25″ x 10.4″ (413 x 264) |

15.2″ x 17.5″ (391 x 368) |

15″ x 15″ (381 x 381) |

AD118-1C | AD118-1A | AD118-1D |

| AD124 | 18.5″ x 24″ x 13.5″ (470 x 610 x 343) |

1 | 21.25″ x 10.4″ (540 x 264) |

20.2″ x 17.5″ (511 x 445) |

15″ x 21″ (381 x 525) |

AD224-1C | AD224-1A | AD224-1D |

| AD218 | 23.5″ x 18″ x 27″ (597 x 457 x 343) |

1 | 21.25″ x 10.4″ (540 x 264) |

20.2″ x 17.5″ (513 x 445) |

20″ x 15″ (508 x 381) |

AD218-1C | AD218-1A | AD218-1D |

| AD224 | 23.5″ x 24″ x 13.5″ (597 x 610 x 343) |

1 | 21.25″ x 10.4″ (540 x 264) |

20.2″ x 23.5” (513 x 597) |

20” x 21″ (508 x 525) |

AD224-1C | AD224-1A | AD224-1D |

| AD112 | 13″ x 12″ x 27″ (305 x 305 x 686) |

2 | 10.75″ x 10.4″ (273 x 264) |

9.5″ x 10″ (241 x 292) |

9.5″ x 10.75″ (241 x 273) |

AD112-2C | AD112-2A | AD112-2D |

| AD116 | 17″ x 16″ x 19″ (406 x 406 x 483) |

2 | 14.75″ x 6.4″ (375 x 163) |

13.5″ x 14″ (343 x 356) |

13.5″ x 13″ (343 x 330) |

AD116-2C | AD116-2A | AD116-2D |

| AD118 | 18.5″ x 18″ x 27″ (470 x 457 x 686) |

2 | 16.25″ x 10.4″ (413 x 264) |

15″ x 16″ (381 x 406) |

15″ x 15″ (381 x 381) |

AD118-2C | AD118-2A | AD118-2D |

| AD124 | 18.5″ x 24″ x 27″ (470 x 610 x 686) |

2 | 16.25″ x 10.4″ (413 x 264) |

15″ x 22″ (381 x 559) |

15″ x 21″ (381 x 525) |

AD124-2C | AD124-2A | AD124-2D |

| AD218 | 23.5″ x 18″ x 27″ (597 x 457 x 686) |

2 | 21.25″ x 10.4″ (540 x 264) |

20″ x 16″ (508 x 406) |

20″ x 15″ (508 x 381) |

AD218-2C | AD218-2A | AD218-2D |

| AD224 | 23.5″ x 24″ x 27″ (597 x 610 x 686) |

2 | 21.25″ x 10.4″ (540 x 264) |

20″ x 22” (508 x 559) |

20” x 21″ (508 x 525) |

AD224-2C | AD224-2A | AD224-2D |

* Acrylic desiccator cabinets are susceptible to damage when cleaned with alcohol or other strong cleaning/disinfecting agents. Desiccator cabinets fabricated out of Static

Dissipative PVC may be a better choice in these instances.

** It is highly recommended that stainless steel shields be installed in Static Dissipative PVC desiccators to protect the chambers bottom surface from repeated scraping and rubbing, which can lead to loss of dissipative properties. Shields also protect acrylic cabinets against scratches on chamber bottom surface

Additional Product Information

- Pre- tapped holes for optional Auto-Adjust™ RB (relief/bleed) valve installation

- Cabinets can be ordered without side racks if maximum inside clearances are needed for product storage

- Amber acrylic desiccator cabinets are ideal for storage of materials and devices that are sensitive to ultraviolet light.

- Static-dissipative PVC desiccator cabinets provide added contamination control by dissipating static charges that attract air-borne particulate.

- Exterior removable back plenum panel is made of non-dissipative material. Static dissipative PVC available upon request (at additional charge).

- Desiccator cabinet nominal dimensions include the side hinge and catch re-enforcement strips, door hinges and access door(s). Please add 1” (25.4mm) for access door compression lift latch (standard cabinet feature) if overall cabinet depth is needed

- Static-dissipative PVC desiccator cabinets feature system grounding, where the door latch set, hinges and racks are interconnected with conductive tape and terminated at a multi lug grounding block. Grounding is optional on clear and amber acrylic desiccator cabinets. See Grounding (desiccator) option below for further information.

- Static dissipative PVC desiccator cabinets should not be exposed to extreme heat, direct sun light or prolonged exposure to temperatures above 80 degrees Fahrenheit.

- It is highly recommended that heavy objects and/or materials not be placed on top of desiccator cabinets unless the cabinet is properly fitted with the optional stainless steel adjustable shelf supports.

- Desiccator cabinets should be periodically cleaned. When doing so, it is recommended that a microfiber cloth be used along with cold to slightly warm water. If needed, a mild non-abrasive detergent may also be used. Starting at the top of the cabinet and working down the sides, gently wipe the desiccator clean using straight (not circular) motions. It is important to turn and even replace the cloth frequently to avoid a cloth that is too dirty as it may create unnecessary scratches.

| Shields, Shelves & Trays Corresponding shields, shelves & trays for AutoDesiccator™ Cabinet |

||||||||

|---|---|---|---|---|---|---|---|---|

| AutoDesiccator Series # |

Shelves / Trays Nominal Inside Usable Dimensions in inches (mm) W x D |

Stainless Steel Non-Perforated |

Electro-Polished Stainless Steel Non-Perforated |

Clear Acrylic* w/ Stainless Steel Flex Guard™ |

||||

| Shield | Shelf, .5″D | Tray, 2″D | Shield | Shelf, .5″D | Tray, 2″D | Shelf, .25″ Material | ||

| Part # | Part # | Part # | Part # | Part # | Part # | Part # | ||

| AD112 | 9.375″ x 9.25″ (235 x 254) |

AD112-SD | AD112-SF | AD112-ST | AD112-SDE | AD112-SDE | AD112-STE | AD112-ASF |

| AD116 | 13.375″ x 13.25″ (337 x 318) |

AD116-SD | AD116-SF | AD116-ST | AD116-SDE | AD116-SDE | AD116-STE | AD116-ASF |

| AD118 | 14.875″ x 15″ (375 x 368) |

AD118-SD | AD118-SF | AD118-ST | AD118-SDE | AD118-SDE | AD118-STE | AD118-ASF |

| AD124 | 19.875″ x 9.25” (502 x 368) |

AD124-SD | AD124-SF | AD124-ST | AD124-SDE | AD124-SDE | AD124-STE | AD124-ASF |

| AD218 | 19.875″ x 15″ (502 x 368) |

AD218-SD | AD218-SF | AD218-ST | AD218-SDE | AD218-SDE | AD218-STE | AD218-ASF |

| AD224 | 19.875″ x 21″ (502 x 521) |

AD224-SD | AD224-SF | AD224-ST | AD224-SDE | AD224-SDE | AD224-STE | AD224-ASF |

Additional Product Information

- Stainless steel shields being purchased for installation on clear and amber acrylic desiccator cabinet’s, should be considered with the addition of desiccator grounding (optional). See Grounding (desiccator) option below for further information.

- Shields are factory installed. When purchased for use with a static-dissipative PVC desiccator, the shields will be installed and connected to the system grounding, which is a standard feature on these cabinets.

- Perforated shields, shelves and trays are available upon request (at additional charge)

Sonic Humidifier™

- Provides a stream of high humidity gas to enclosures that require higher then ambient R/H level

- Automatically generates moisture using a sonic transducer and a connected water source

- Can be used for environmental testing of a large variety of devices to determine performance in wet conditions

- Works in conjunction with the Gas Purge™ and Gas Monitor™ control systems to maintain a specific R/H set point

- Works with120/240VAC, 50/60Hz, and requires no manual power selection

For actual control of the humidity level, the Sonic Humidifier™ must be used in conjunction with the Gas Purge™ and Gas Monitor™ control systems.

| Sonic Humidifier™ |

|---|

| Part # |

| SH-1A |