Gas Control Solutions

Flow Meters:

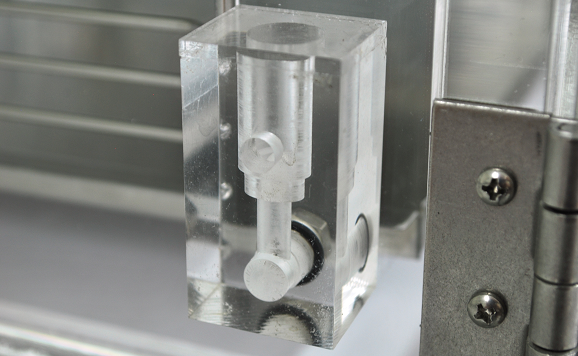

- Scales are hot stamped into the front of the acrylic body and will not wear off

- Bodies are precision cut and machined from clear acrylic blocks with a smooth tapered bore that provides perfect visibility of the indicating float

- Accuracy is ±5% of full scale with a scale average 2″ long

- Features brass (stainless steel optional) inlet and outlet connections, black glass float, Buna-N O-rings and tapped for 1/8″ NPT female process connection (vertical mounting)

- Service: Compatible gases and liquids

- Includes nickel plated brass hex nipple and 90 degree elbow (female x male), 1/8” (3.18mm) pipe size for connection to Cleanroom Synergy desiccators, glove boxes or other gas purged enclosures

| Flow Meter (fittings included) | ||

|---|---|---|

| ,6 – 5 SCFH | 1 – 10 SCFH | 2 – 20 SCFH |

| Part # | Part # | Part # |

| CCE-FME | CCE-FMH | CCE-FMK |

Auto-Adjust™ RB Valve:

- Automatically adjusts to gas flow rates and possible sudden surges

- Eliminates possible negative pressure incidents due to its one way air flow design

- Continuously bleeds off excess internal gas to maintain a safe pressure within desiccators, glove boxes and other hermetically sealed enclosures

- Includes a nickel plated brass hex nipple fitting (1/8” NPT) with a polyurethane O-ring to ensure a positive seal against the hermitically sealed enclosure

- One Auto R/B Valve per cabinet is required if desiccator is to be purged with dry gas

- Installation of one Auto-Adjust™ RB Valve in each desiccator storage chamber eliminates cross contamination and R/H fluctuation in the unopened chambers

Gas Purge™ Control System:

- Automatically activates a high-flow gas purge when a chamber door is accessed

- Protects moisture sensitive materials against oxidation, increasing product yield

- Ensures a constant positive pressure within glove boxes and other hermetically sealed enclosures to block out contamination influx

- Dramatically reduces purge gas cost when compared to systems using only a mechanical flow meter

- Adjustable electronic flow meter precisely regulates the flow rate of the purge gas

- Digital pressure regulator safely adjusts the pressure of the incoming gas

- Operates in conjunction with the optional Gas Monitor™ Control Unit to maintain desired sub-ambient moisture level (down to 0% RH)

- High-reliability door switches are rated for millions of operations. One per desiccator chamber required

- Works with120/240VAC, 50/60Hz, and requires no manual power selection

The Gas Purge™ Controller monitors and regulates the dry gas that will flow into the desiccator when it is needed to lower the R/H or when a chamber door is opened. It has a gas regulator to control the pressure of the incoming gas and electronic flow meter that regulates and maintains the low flow of gas. Also provides audible/visual warnings when the supply gas is getting low, a desiccator door has been left opened or if the R/H set point has not been reached.

| Gas Purge™ Controller |

Sensor Switch |

|---|---|

| Part # | Part # |

| GPC-D1 | GPC-D1S |

|

One sensor switch required per desiccator chamber

|

|

Gas Monitor™ Control System

- The Gas Monitor™, when used in conjunction with the Gas Purge™ Controller will automatically maintain desiccator R/H levels from ambient down to R/H of the purge gas (0% for most dry gases)

- Incorporates a state of the art micro-controller, a bright readable R/H display and simple control buttons

- Since the desiccator only needs gas when the R/H rises above the set point, it uses much less gas resulting in large cost savings

- Small solid state humidity sensor never needs calibration, easily installed and takes a small amount of desiccator space

- Can be used to monitor R/H levels in any enclosure without the use of the Gas Purge™ controller

- Works with120/240VAC, 50/60Hz, and requires no manual power selection

The Gas Monitor™ controller measures the R/H of the chamber which contains the Gas Sensor. It has provisions to enter a desired R/H set point and will issue a command to the Gas Purge™ controller to lower the desiccator cabinet’s humidity level whenever it senses a reading above the R/H set point. It also monitors the open and closed positions of the desiccator doors and issues a command to the Gas Purge™ controller to introduce dry gas at a high flow rate while the door is opened and for a preset time after the door is closed (factory set at 60 seconds).

| Gas Monitor™ Controller |

Gas Monitor™ Sensor |

|---|---|

| Part # | Part # |

| GMC-1 | GMC-1S |

Sonic Humidifier™:

- Provides a stream of high humidity gas to enclosures that require higher then ambient R/H level

- Automatically generates moisture using a sonic transducer and a connected water source

- Can be used for environmental testing of a large variety of devices to determine performance in wet conditions

- Works in conjunction with the Gas Purge™ and Gas Monitor™ control systems to maintain a specific R/H set point

- Works with120/240VAC, 50/60Hz, and requires no manual power selection

For actual control of the humidity level, the Sonic Humidifier™ must be used in conjunction with the Gas Purge™ and Gas Monitor™ control systems.

|