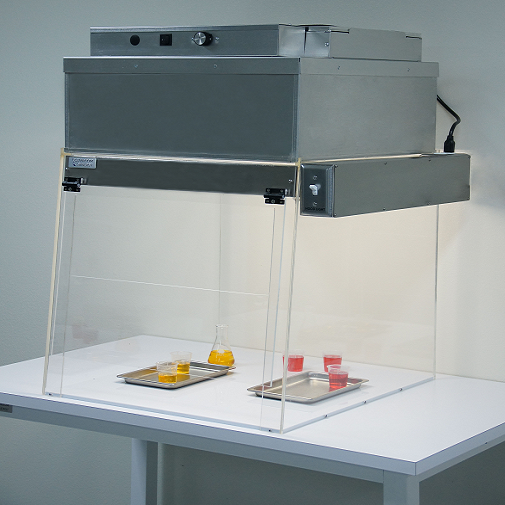

Flex™ Laminar Flow Hood

- Provides an economical, ISO 5 (Class 100) work environment

- Integrated white polypropylene base provides a clean and chemical resistant work surface

- Adjustable front access shield features friction hinges for safe positioning

- Washable pre-filter, on/off switch for blower operation, *variable speed control and an 8’ long power cord

- Modular design allows hood configuration for application specific requirements

- Portability for convenient placement on most any bench or counter top

- Provides an ideal workspace environment for sensitive manufacturing, assembly and testing operations

- Light Shield/Control Box Interface (optional) provides on-demand fluorescent lighting and integration of all system electrical components

- Ionization system (optional) introduces both positive and negative ions that neutralizes charge that would otherwise damage static sensitive devices

- Standard system voltages include 120VAC 50Hz and 240VAC 50/60Hz

- Available in a variety of sizes and materials, including static dissipative PVC for added contamination control and chemical resistance

Cleanroom Synergy’s, Flex™ Laminar Flow Hood line offers a list of standard sizes, materials and voltages to choose from, allowing each clean air hood to be configured to suite the application in which it will be used. An integrated white polypropylene work surface increases the strength and integrity of the hoods structural body and allows the hood to be placed on most any available flat surface. The hinged access shield, when in the up position, provides a large opening for easy placement of materials and process equipment……and in the down position, the access shield helps to increase the exiting air velocity, eliminating contamination influx while still providing the operator with ample access to the work area. Positive clean air flow is provided by an industry leading low noise (nominally 50Dba) motorized fan HEPA (99.99% efficient @ .3micron) filter unit, creating an ultra-clean ISO 5 (Class 100) work environment.

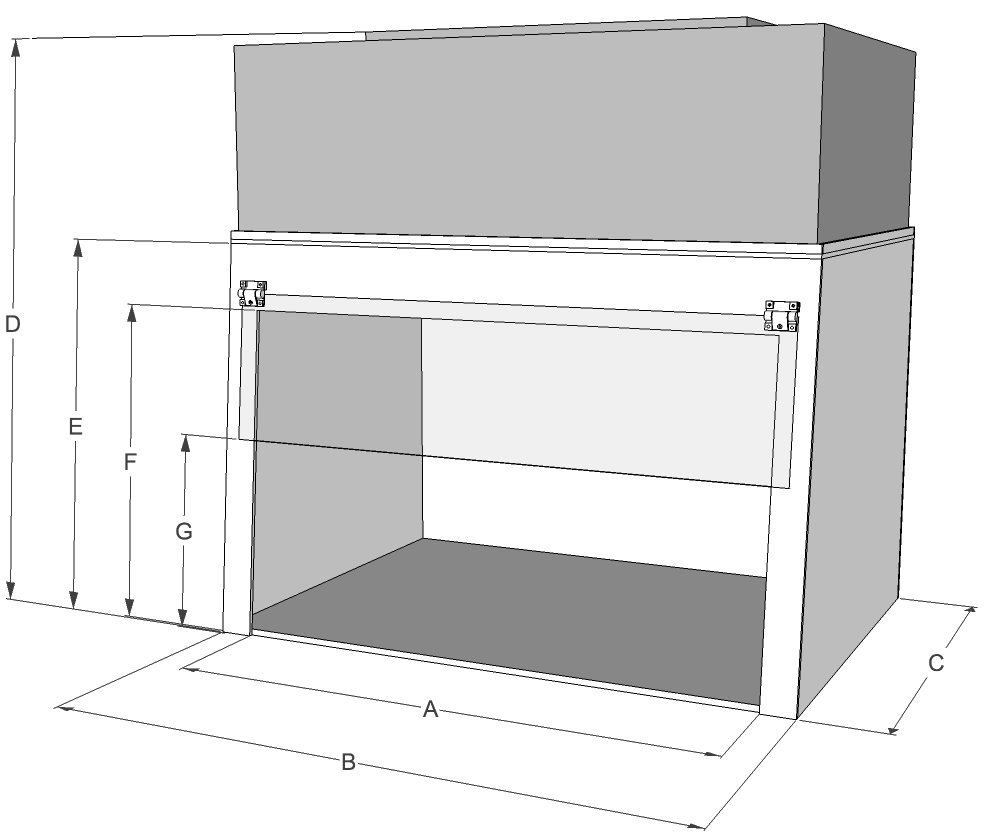

| Flex™ Laminar Flow Hood Nominal Dimensions in Inches (mm) | |||||||

|---|---|---|---|---|---|---|---|

| Hood Size | A | B | C | D | E | F | G |

| Small | 20.25″ (514) | 24.25″ (616) | 26.25″ (667) | 36″ (914) | 23.25″ (591) | 19.25″ (502) | 11.75″ (298) |

| Medium | 32.25″ (819) | 36.25″ (920) | 26.25″ (667) | 36″ (914) | 23.25″ (591) | 19.25″ (502) | 11.75″ (298) |

| Large | 44.25″ (1124) | 48.25″ (1225) | 26.25″ (667) | 36″ (914) | 23.25″ (591) | 19.25″ (502) | 11.75″ (298) |

Standard Laminar Flow Clean Air Hood Material Options:

- Acrylic (cast) – Ideal for general purpose processing. Provides some chemical resistance

- Polycarbonate – High impact resistance makes this material ideal for thermal stress applications. Provides good chemical resistance

- Polypropylene – Provides the best chemical resistance

- Non-Dissipative PVC – Provides excellent chemical resistance

- Static Dissipative PVC – Provides excellent chemical resistance. Also helps to reduce contamination build-up around and within the glove box by neutralizing static charges that attracts air borne particulate

Additional product information:

- Small and medium clean air hoods feature a solid-state speed controller and large hoods feature a three-speed switch (low-med-high)

- Access shields are made from the same material as the hood itself with exception to the polypropylene hood, which features a non-dissipative PVC access shield

(Custom sizes available upon request)

| Flex™ Laminar Flow Hood (for 120VAC, 50Hz use) | |||||

|---|---|---|---|---|---|

| Hood Size (see drawing below for hood dimensions) |

Acrylic | Polycarbonate | *Polypropylene | Static Dissipative PVC |

Non Dissipative PVC |

| Part # | Part # | Part # | Part # | Part # | |

| Small | FLF2-A1 | FLF2-C1 | FLF2-P1 | FLF2-D1 | FLF2-N1 |

| Medium | FLF3-A1 | FLF3-C1 | FLF3-P1 | FLF3-D1 | FLF3-N1 |

| Large | FLF4-A1 | FLF4-C1 | FLF4-P1 | FLF4-D1 | FLF4-N1 |

| Flex™ Laminar Flow Hood (for 240VAC, 50/60Hz use) | |||||

|---|---|---|---|---|---|

| Hood Size (see drawing below for hood dimensions) |

Acrylic | Polycarbonate | *Polypropylene | Static Dissipative PVC |

Non Dissipative PVC |

| Part # | Part # | Part # | Part # | Part # | |

| Small | FLF2-A2 | FLF2-C2 | FLF2-P2 | FLF2-D2 | FLF2-N2 |

| Medium | FLF3-A2 | FLF3-C2 | FLF3-P2 | FLF3-D2 | FLF3-N2 |

| Large | FLF4-A2 | FLF4-C2 | FLF4-P2 | FLF4-D2 | FLF4-N2 |

* Acrylic is susceptible to damage with the prolonged use of alcohol and other cleaning/disinfecting agents.

Product Options & Customization

Light Shield/Control Box Interface

Integration of the Light Shield/Control Box Interface into a Flex™ Laminar Flow Hood provides direct fluorescent lighting over the hoods work area and interconnection of system components into a single code compliant electrical box.

- The wrap design of the 304 stainless steel Light Shield directs the fluorescent light at the work surface and not into the eyes of the operator

- The 304 stainless steel Control Box integrates the hood, the light shield and the motorized fan filter unit into a single, stand-alone system. Features include an on/off switch for fluorescent light operation, an 18” long power cord on the HEPA filter unit, a duplex outlet and an 8’ long main power cord. One side of the duplex is marked “HEPA filter” and the other marked “spare”.

- Factory installed with the wire interface between the Light Shield and the Control Box via a liquid-tight bulkhead fitting

| Light Shield/Control Box Interface | ||

|---|---|---|

| Hood Size | 120V, 50Hz | 240V, 50/60Hz |

| Part # | Part # | |

| Small | LS2-CB1 | LS2-CB2 |

| Medium | LS3-CB1 | LS2-CB2 |

| Large | LS4-CB1 | LS2-CB2 |

Power Strip

- Provides an convenient electrical connection for process equipment being used within the clean processing environment

- Mounted horizontally on the inside rear wall 3” from the bottom work surface

- Includes a master on/off switch, 4-outlets and a 15-amp circuit breaker

| Power Strip |

|---|

| Part # |

| LF-PS-4 |

Spill Containment Tray

- Provides containment of liquid spills within the Purge™ Laminar Flow Hood or the Flex™ Laminar Flow Hood

- Fabricated out of ¼” (6.35 mm) white, chemical resistant polypropylene

- Removable for easy clean-up or storage when not needed

| Spill Containment Tray | ||

|---|---|---|

| Hood Size | Tray Nominal Inside Dimensions in inches (mm) |

Part # |

| Small | 17.5″W x 23.5″L x 1″D (445 x 597 x 6) |

SCT-2 |

| Medium | 29.5″W x 23.5″L x 1″D (749 x 597 x 6) |

SCT-3 |

| Large | 41.5″W x 23.5″L x 1″D (1054 x 597 x 6) |

SCT-4 |

Ion Power Bar™

- Enhances cleanliness within the hood by neutralizing static charges that attract air-borne contaminates

- Continuous generation of static neutralizing ions help to protect static sensitive materials/devices from electro-static discharge

- Ionizing bar mounts below the HEPA filter unit providing optimized distribution of both positive and negative ions

| Ion Power Bar™ | ||

|---|---|---|

| Hood Size | 120V, 50Hz | 240V, 50/60Hz |

| Part # | Part # | |

| Small | ION-2B-1 | ION-2B-2 |

| Medium | ION-3B-1 | ION-3B-2 |

| Large | ION-4B-1 | ION-4B-2 |