Micron-Aire™ Large “Single Tier” Plastic Desiccator Cabinets / Dry Boxes

|

|

|

|

| Micron-Aire™ Large “Single Tier” Plastic Desiccator Cabinets / Dry Boxes | |||||||

|---|---|---|---|---|---|---|---|

| Type | Desiccator Series # |

Desiccators Nominal Overall Cabinet Dimensions in inches (mm) W x D x H |

Number of Chambers |

Stainless Steel Shelves / Trays Nominal Inside Usable Dimensions in inches (mm) W x D |

Clear Acrylic* |

Amber Acrylic* |

Static Dissipative PVC** |

| Part # | Part # | Part # | |||||

| G | D118 | 18.5″ x 18″ x 36″ (470 x 457 x 914) |

3 | 15″ x 15″ (381 x 381) |

D118-3C | D118-3A | D118-3D |

| D124 | 18.5″ x 24″ x 36″ (470 x 610 x 914) |

3 | 15″ x 21″ (381 x 525) |

D124-3C | D124-3A | D124-3D | |

| D218 | 23.5″ x 18″ x 36″ (597 x 457 x 914) |

3 | 20″ x 15″ (508 x 381) |

D218-3C | D218-3A | D218-3D | |

| D224 | 23.5″ x 24″ x 36″ (597 x 610 x 914) |

3 | 20” x 21″ (508 x 525) |

D224-3C | D224-3A | D224-3D | |

| H | D118 | 18.5″ x 18″ x 48″ (470 x 457 x 1219) |

4 | 15″ x 15″ (381 x 381) |

D118-4C | D118-4A | D118-4D |

| D124 | 18.5″ x 24″ x 48″ (470 x 610 x 1219) |

4 | 15″ x 21″ (381 x 525) |

D124-4C | D124-4A | D124-4D | |

| D218 | 23.5″ x 18″ x 48″ (597 x 457 x 1219) |

4 | 20″ x 15″ (508 x 381) |

D218-4C | D218-4A | D218-4D | |

| D224 | 23.5″ x 24″ x 48″ (597 x 610 x 1219) |

4 | 20” x 21″ (508 x 525) |

D224-4C | D224-4A | D224-4D | |

| I | D118 | 18.5″ x 18″ x 60″ (470 x 457 x1514) |

5 | 15″ x 15″ (381 x 381) |

D118-5C | D118-5A | D118-5D |

| D124 | 18.5″ x 24″ x 60″ (470 x 610 x 1514) |

5 | 15″ x 21″ (381 x 525) |

D124-5C | D124-5A | D124-5D | |

| D218 | 23.5″ x 18″ x 60″ (597 x 457 x 1514) |

5 | 20″ x 15″ (508 x 381) |

D218-5C | D218-5A | D218-5D | |

| D224 | 23.5″ x 24″ x 60″ (597 x 610 x 1514) |

5 | 20” x 21″ (508 x 525) |

D224-5C | D224-5A | D224-5D | |

* Acrylic desiccator cabinets are susceptible to damage with the prolonged use of alcohol and other cleaning/disinfecting agents. Desiccator cabinets fabricated

out of Static Dissipative PVC may be a better choice in these instances.

** It is highly recommended that stainless steel shields be installed in Static Dissipative PVC desiccators to protect the chambers bottom surface from repeated

scraping and rubbing, which can lead to loss of dissipative properties.

Additional product information:

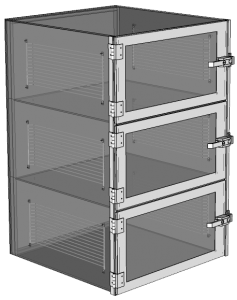

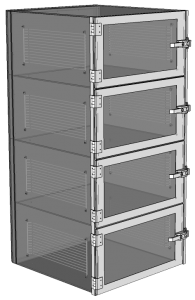

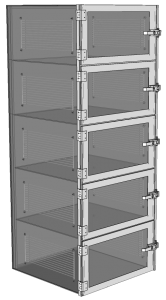

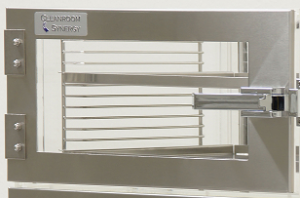

- The above reference 3D renderings shown with optional stainless steel door frames, which are listed below.

- Amber acrylic desiccator cabinets are ideal for storage of materials and devices that are sensitive to ultraviolet light.

- Pre- tapped inlets/outlets for connection of optional gas purge devices & controllers and Auto-Adjust™ RB (relief/bleed) valve.

- Static-dissipative PVC desiccator cabinets provide added contamination control by dissipating static charges that attract air-borne particulate.

- Exterior removable back plenum panel is made of non-dissipative material. Static dissipative PVC available upon request (at additional charge).

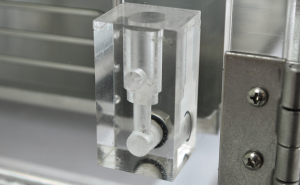

- Static-dissipative PVC desiccator cabinets feature system grounding, where the door latch set, hinges and racks are interconnected with conductive tape and terminated at a multi lug grounding block. Grounding is optional on clear and amber acrylic desiccator cabinets. See Grounding (desiccator) option below for further information.

- Desiccator cabinet nominal dimensions include the side hinge and catch re-enforcement strips, door hinges and access door(s). Please add 1” (25.4mm) for access door compression lift latch (standard cabinet feature) if overall cabinet depth is needed

- Static dissipative PVC desiccator cabinets should not be exposed to extreme heat, direct sun light or prolonged exposure to temperatures above 80 degrees Fahrenheit.

- It is highly recommended that heavy objects and/or materials not be placed on top of desiccator cabinets unless the cabinet is properly fitted with the optional stainless steel adjustable shelf supports.

- Desiccator cabinets should be periodically cleaned. When doing so, it is recommended that a soft, nonabrasive cloth (micro-fiber) be used along with cold to slightly warm water. If needed, a mild non-abrasive detergent may also be used. Gently wipe the desiccator clean using straight (not circular) motions, replacing the cloth frequently to avoid any un-necessary scratching of the plastic surfaces.

| Small “Single Tier” Desiccators Click for Ordering Information |

Large “Single Tier” Desiccators Click for Ordering Information |

Large “Double Tier” Desiccators Click for Ordering Information |

Relative Humidity & Static Control Solutions

Relative Humidity Control:

For automated control over low R/H levels (0% to ambient RH) or for complete R/H control (0% – 100%), select the optional Gas Purge™, Gas Monitor™ and

Sonic Humidifier™ control systems listed in the “Gas Control Solutions” section of this page. Click here for additional information

Static Control Solutions:

- Conductive stainless steel shields, shelves and trays, which when grounded and properly positioned can create a Faraday cage that prevents

penetration of electric fields and the resulting static charges. Stainless steel shelves and trays can also help to protect static sensitive

materials from electro-static discharge when transporting materials from one location to another. See the following ordering charts - Desiccator grounding (standard on static dissipative PVC cabinets) provides interconnection of the racks, latches and stainless steel hinges

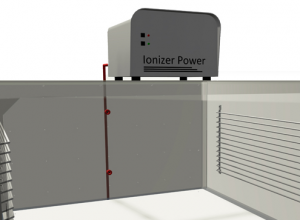

with conductive tape and terminated at a multi-lug grounding block. Click here for additional information - Ion Power™ Unit and ionizing nozzles provide positive and negative ions into desiccator cabinet storage chambers to neutralize static charge

build-up. Click here for additional information

Product Options & Customization

Stainless Steel Door Frames:

|

|

|

||||||||||||||

Shields, Shelves & Trays:

* Acrylic shelves should not be used with static-dissipative PVC desiccator cabinets.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Shelf Supports:

Note: It is recommended that stored materials, whenever possible, be distributed evenly though-out the storage |

|

||||||||||||

Floor Stands & Casters:

|

Casters:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas Control Solutions

Flow Meters:

|

|

||||||||||||

Auto-Adjust™ RB Valve:

|

|

|||

|

|

Gas Purge™ Control System:

The Gas Purge™ Controller monitors and regulates the dry gas that will flow into the desiccator when it is needed to lower the R/H or |

|

|||||||

|

||||||||

Gas Monitor™ Control System

The Gas Monitor™ controller measures the R/H of the chamber which contains the Gas Sensor. It has provisions to enter a desired R/H set point and |

|

|||||||

|

||||||||

Sonic Humidifier™:

For actual control of the humidity level, the Sonic Humidifier™ must be used in conjunction with the Gas Purge™ and Gas Monitor™ control systems. |

|

||

|

Static Control Solutions

Grounding (Desiccator):

Notes:

|

|

|

||||

|

|

||||||

| Desiccator Cabinet Grounding: Static Dissipative PVC features a surface resistivity of approximately 107 ohms/square that dissipates static charges from the cabinet’s surface. Grounding is standard on Static Dissipative PVC desiccators, which safely directs charges to a multi lug termination grounding block. To protect the Static-Dissipative PVC interior bottom surface, it is “highly recommended” that a stainless steel shield be installed in each desiccator cabinet chamber. Stainless steel shield installation includes connection to the desiccators grounding.Acrylic (clear and amber) desiccators can also be fitted with grounding by purchasing the optional “Desiccator Grounding”. Charge for the desiccators grounding is per chamber. Stainless steel shield installation within these cabinets, include connection to the desiccators grounding if optional grounding is purchased. |

||||||

Ion Power™ Unit

|

|

|

|||

|